The system includes four robots from KUKA and makes it possible to neatly stack steel profiles from 4.5 to 13 meters in length.

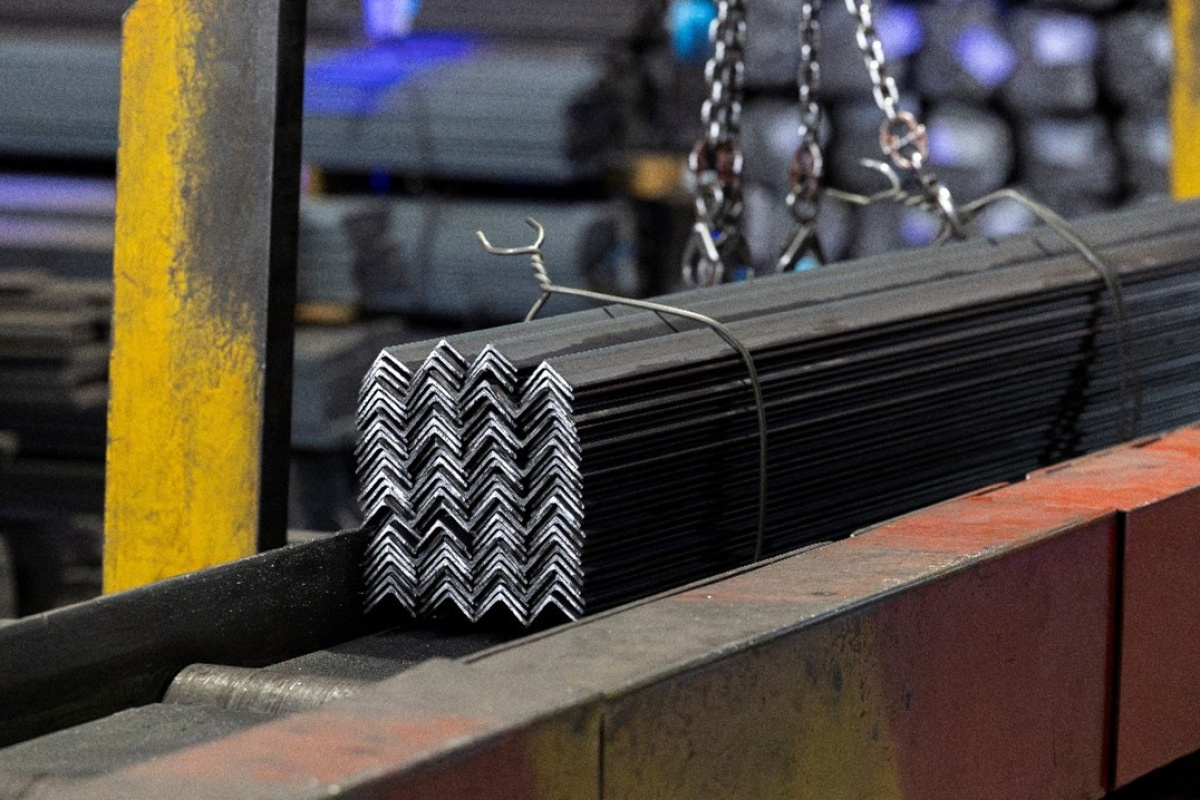

The work included the complete automation of the system and the insertion of a robotic stacker divided in four anthropomorphic robots from KUKA. The system processes small L types merchant bars and flat profiles, and allows the expansion of the product range mainly with angles from 25x25mm to 60x60mm in size and width from 3 to 7 mm.

A special feature of the system is that it is able to shift from one profile to another: the set-up of the machine is very simple and fast to change, in 7 minutes a single operator is able to reequip the robot for a new profile. The system is very flexible, and depending on requirements it is possible to stack from above and below the profiles or alternatively stack it in a mixed way, this flexibility is useful to reduce stacking cycle times and to form tidier packs.

AIC integrated the bar stackers into the existing structure in order to allow the robot to pick up the layers in a straight and reverse way. In order not to modify mechanically the existing machine, the bar stackers were designed independently in the electrical axis. The robotic solution chosen by the customer made it possible to reuse the existing plant in its entirety with only the integration of the robots for the formation of the unprocessed profile bundles. The addition of bar stackers allowed the reverse layer collection without invasive modifications. This allowed the project to be completed in just 6 weeks of downtime.

The system is particularly flexible to handle different processed products, the stacker can switch between flat and angular products, and there is no need to reprogram the robot to change processes. By using complex control algorithms, the system monitors the picking and depositing of the correct layer of bars and stops automatically if it detects any anomalies. Depending on the stacking recipe, the robot automatically and dynamically adapts to pick up and deposit the various layers.

Share on: